Research Projects of All Chairs

Towards Drilling Automation: A Platform to Plan, Perform, and Monitor the Drilling Operation Automatically

Towards Drilling Automation: A Platform to Plan, Perform, and Monitor the Drilling Operation Automatically

There is no doubt of the complexity of drilling processes due to the enormous components and uncertainties engaged in the flow. It is evident that because of the cost associated with having sensors along the drilling string, most of the sensors are located on the surface. Thus few downhole measurements are available in real-time. Therefore, it causes a limited observation of the drilling process and leads to greater difficulty when applying standard control methods.

Furthermore, detecting the actual current state of the operation with sparse downhole information requires more effort and investigation. Consequently, achieving a fully autonomous drilling sequence has two main requirements. The first is a method to represent the states to control the operation. The second is that the technique must frequently update the plan based on the last activity and the current state.

The final objective of the drilling operation is to minimize the time needed to reach total section depth (TD), which directly reflects the cost. All this must be done while keeping the associate (short and long term) risk at an acceptable level. This goal needs to be fulfilled in different finite horizons, from the next few minutes of the operation, up to the whole drilling operation. This research will develop a solution for evolving an autonomous decision-making system considering the aforesaid concerns.

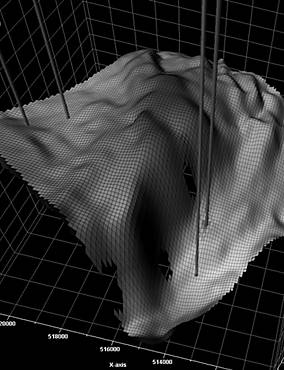

CCS Data Analytics

Bring emissions down towards net zero simultaneously with meeting the energy demand, will be one of the world’s biggest challenges in the years ahead. CCS is the only technology that can effectively reduce CO2 emissions in a short time.

From the technical point of view, CCS is a mature technology with more than 50 years’ experience, hence it is the least expected technology to fail, however a recent report of IEEFA (2022) concluded that the failed projects considerably outnumbered the successfully implemented ones. While the technological expertise is already in place, the nature of scaling up its storage capacity is inherently interdisciplinary depending on also other socio-political dynamics of CCS. This is what the author wishes to achieve here. To detect and quantify the most important factors in the accomplishment of CCS projects and to develop models to predict the chance of the coming project success.

It is the production of energy that is responsible for almost 90% of global greenhouse gas emissions. Moreover, Fossil fuels including oil & gas are not only the primary source of world energy consumption now but also they are expected to remain the main source until 2030 and further on for a while.

----

We3D Innovative Additive Manufacturing Applications in Downhole Operations

We3D Innovative Additive Manufacturing Applications in Downhole Operations

In cooperation with 22 business and academic partners, DPE is bringing forward a new generation of Wire-based Additive Manufacturing (WAM). The overall project’s goal is to produce high quality 3D alloy components, innovative methods and technologies using WAM. All this is to be done whilst simultaneously reducing the cost, environmental impact, and time taken. Metal Additive Manufacturing (MAM) is one of DPE’s many fields of studies, with the Chair of Drilling and Completion already having completed a series of research projects on this topic.

While previous MAM projects at DPE focused on producing spare parts for the oil and gas industry, We3D tackles challenges in the wellbore, specifically in downhole operations. Thus, the technology has to be developed to withstand harsh environments and constrained positions.

With this innovation, the industry will experience an alternative, rigless technology with the potential to revolutionize downhole operations. As the work could be done without larger and cost-intensive drilling rigs, significant cost reductions with smaller work-over units will be expected. Thus, bringing about an entire new way of applying additive manufacturing to solve complex challenges in the oil and gas industry.

Interested in this project? Contact Sharen Leon.

For more information visit AIT We3D project.

A Method and System for Detecting Undesirable Drilling Events

Momentarily, the drilling process is a manual labor driven operation in which the decisions made, mainly rely on surface measurements and sometimes the gut feeling of experienced people. To rely on such information might be acceptable for performance-driven operations such as making a connection or tripping pipe. At the point, when it comes down to critical tasks such as kick and losses detection or defining cement quality, profound and valid background knowledge is needed to make the correct decisions in real time. Thus, the main objective of this project is to develop a new and time-efficient concept for real time detection and verification of the most common undesirable drilling events such as losses, kicks, stuck-pipe, string failure and wellbore instability.

Data and Expert Driven Workflow for Application of Automatic Adaptive Algorithm in Well Operations

Data and Expert Driven Workflow for Application of Automatic Adaptive Algorithm in Well Operations

Mast.inz.rud.

Miroslav

Mast.inz.rud.

Miroslav Antonic

In today's data extensive world, the oil and gas industry has been evolving by developing advanced diagnostics and optimization tools based on artificial intelligence techniques that are data driven. Most autonomous workflows are built on a foundation of statistical analysis and the implementation of artificial intelligence techniques based on real-time data, without the integration of reservoir/well models. However, this raises the crucial questions of how to predict critical dynamical conditions when the well requires long term actions (workover, sand control, chemical application, etc.) and how to maintain optimal well conditions.

Thus far, the Automatic Adaptive Algorithm (A3) is an innovative concept of smart diagnostic and well performance optimization based on real-time data and guidelines. The research focuses on avoiding problems with downhole equipment and excessive sand production by allowing condition monitoring of downhole equipment to keep the production rate, pressures, and temperature at an optimum level.

The proper regulations could help the industry increase the production of low productivity wells according to the conditions in the well/reservoir and prevent premature failures of downhole equipment.

Flow Digitalization

To ensure well integrity throughout the entire life cycle of the well it is of paramount importance to achieve an effective placement of the cement slurry and bonding to casing and formation. Cement as a well barrier element is not only necessary during the operational phase of the well but also later during plugging and abandonment. The cement slurry is pumped down the wellbore where it finally hydrates in the annular space between the casing and the formation or between two casing strings. A stable cement bond is important in order to provide zonal isolation and to prevent the unwanted flow of formation fluids as well as to mechanically support the casing or liner strings in the wellbore.

To ensure an effective cement placement without any contamination, the removal of drilling fluid is of major importance. In order to prepare the annular space for the upcoming cement job, so-called pre flushes and/or spacer fluids are pumped downhole in order to clean the casing wall respectively the formation from the remaining mud. A number of commercial software are available in the industry to simulate the cement slurry placement. However, validation of the results from these software are very limited. Therefore, real-time measurements, at least in the laboratory environment to begin with are of great interest.

The scope of this work is to introduce an accurate flow simulation set-up in a laboratory environment, which is capable of testing the displacement respectively cleaning efficiency of diverse spacer fluids by continuous monitoring real-time data during the displacement of the drilling mud and the hydration process of the cement. Furthermore, the experimental set-up will be used to validate the results, delivered by drilling and cementing software.

A digitalized flow setup will be used to measure parameters using sensors and comparing results predicted by the commercial software. The sensors will be initially installed in a vertical setup and their function verified before upgrading the setup to inclined and horizontal configuration.

Investigation of Additive Manufacturing of Components for the Oil & Gas Industry

Investigation of Additive Manufacturing of Components for the Oil & Gas Industry

Additive manufacturing (AM) is widely used by engineers as a rapid prototyping technology. Currently, the AM technology is transitioning from rapid prototyping to rapid production. This allows the industry to take advantage of the just-in-time strategy, an inventory-based approach that can reduce costs and improve efficiency. Metal AM enables the creation of complex geometries by adding thin layers of metal on top of each other without the need for tooling or assembly. This project focuses on the proof of concept (POC) of applying 3D printing/additive manufacturing in upstream and downstream oil & gas. Suitability of metal-powder materials for the oil & gas industry and how they can be used for manufacturing goods will be evaluated. Parts manufactured in POC phase will be tested in a relevant environment to investigate durability and if the specifications are met.

Real-Time Monitoring of the Effect of CO2 on the Cement Sheath

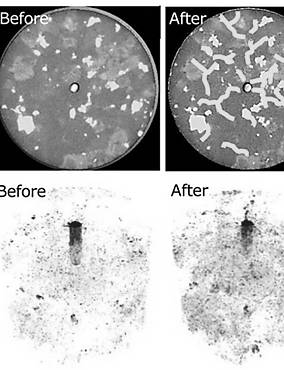

Global warming is one of the biggest issues the world is facing. Capturing CO2 from the atmosphere and storing it in geological formations can help counteract climate change. Nevertheless, its interaction with well barrier elements such as cement, casing, tubulars, packers and valves can lead to possible leakages. During CO2 sequestration, CO2 is injected into a geological formation in its super critical state. The super critical CO2 can corrode steel and elastomers and react with the calcium compounds in the cement, dissolving them and forming calcium carbonate and bicarbonate in the process. This can lead to channels forming on the cement-to-rock interface or cracking due to the carbonate precipitation, resulting in a loss of well integrity.

The aim of this study is to find ways to continuously monitor the integrity of wellbore cement under in-situ conditions. For this purpose, an autoclave, able to withstand the CO2 in its supercritical state, has been constructed. This autoclave also facilitates CT-scans of the pressurized sample, as well as acoustic measurements, using state-of-the-art piezo elements. The first tests will be done using neat Class G Portland cement, to verify the design and sensors. The test set-up consists of a rock core with a channel in the middle to ensure an even distribution of CO2, which will be cemented into the autoclave-cell. Once the ability of the sensors to monitor the integrity is verified, different cement compositions and their interaction with supercritical CO2 will be studied.

The experimental setup and the procedure discussed closely simulate the downhole condition. Hence, the results obtained using this setup and procedure are representative of what could be observed downhole. The cement sample is not removed from the cell and is analyzed under in-situ conditions; digitalization powers the in-situ analysis in this experiment. In addition, the effect of rock permeability is also considered and included in this study. The results from this study can be used to prevent leakage of CO2 to the environment and/or other formations and nullify the disadvantages of CO2 sequestration. This should improve the economics of these wells as well as the health, safety and environment.

Surface Kick and Loss Events Detection

It is agreed that mitigating the impact of the kick and lost circulation on the drilling operation requires an efficient system, which helps to detect the kick and losses as early as possible to be able to take the necessary action on time. Continuously monitoring the drilling fluid surface and velocity inside the bell nipple might be the quickest surface measurement to detect loss and kick events.

Therefore, the main objective of this project is to develop a new concept for detecting kick and loss in the shortest possible time by using the bell nipple as a place to install the required instruments and measure the related parameters.

Error Analysis and Estimation of Real-Time Drilling Data and Operations

Dipl.-Ing.

Anton

Dipl.-Ing.

AntonLettner

In modern society, digitalization is the key to a company’s survival. Many oil and gas companies are currently implementing digitalization initiatives, but struggle to leverage the full potential of the technology. To do so, a holistic understanding of the complex interactions and dependencies of all involved technologies and operations is required. Therefore an in-depth process chain analysis from initial planning to the final decision making is carried out to identify the shortcommings of the current design and to develop comprehensive solutions.

Long-term Cement Integrity

As justified by reported incidents, the role of wellbore cement being a competent barrier for up-hole hydrocarbon flow is questionable. In particular, it is not clear whether the integrity of the bond and seal between the cement and formation or cement and steel-casing is sustained throughout the lifecycle of well operations and beyond.

The cement/casing and cement/rock interface of a cemented annulus is a brittle material-composite. During well operations the bond is subject to static and dynamic stress loads. The risk of bond failure depends on the load frequency, its magnitude, and intrinsic properties of the bond between the cement and casing, as well as the cement and rock.

This research project proposes to apply a certain low number of stress cycles on a cement/casing and cement/rock annular composite to evaluate the low cycle fatigue strength of the bond. Hence, innovative laboratory fatigue testing concepts will be developed in parallel with cutting edge testing apparatus. This will allow the application of static and dynamic axial loads (compression/tension) on an annular cement/casing and cement/rock bond. The experimental results will be compared to finite element/finite differences modeling results for validation.

CFD Analysis of Gas Kick Scenarios

Ao.Univ.-Prof. Dipl.-Ing. Dr.techn.

Wilhelm

Ao.Univ.-Prof. Dipl.-Ing. Dr.techn.

WilhelmBrandstätter

Dipl.-Ing. Dr.mont. MBA

Claudia

Dipl.-Ing. Dr.mont. MBA

ClaudiaGruber

A gas-kick is a fundamentally transient event accompanied by many unknowns. Common approaches in kick modeling are based on the assumption of a more or less single “gas bubble” present in the annulus and slowly migrating upwards after shut-in. While this assumption satisfies straightforward volumetric well control aspects, it ignores species transport and chemical reaction kinetics leading to drill string corrosion.

The intention in this project was to make no a-priory assumptions regarding the evolving flow field. Instead focus was put on a spatially highly resolved model covering the near bottom-hole section of the wellbore where two-phase interactions could be observed at a close-up view.

The project illustrates the value of CFD simulations to verify flow conditions and to support the design process of new measurement tools for early kick detection.

REMAIN: Remote Activation of Geological Interface

Funded by FWF, in collaboration with researchers in Tohoku University, the Chair of Geoenergy Production Engineering launched a fundamental research project to unravel the underlying mechanisms and develop new models to predict how fractures nucleate and propagate and how fault instability initiates under the realistic high-pressure and high-temperature conditions of the subsurface, where fluid and rock behave differently.

For a sustainable, carbon-neutral future, subsurface engineering applications offer promising solutions such as enhanced geothermal systems (EGS) or underground energy storage. When storing or extracting energy in the subsurface, it is essential to ensure environmental safety - such as caprock integrity or induced seismicity - which requires predictive capabilities regarding how fluids like water, supercritical CO2, and hydrogen interact with rock formations. These fluids can create complex fracture networks, which are crucial for improving heat extraction in EGS and ensuring the safe storage of energy. However, they can also trigger seismic events, which have led to the early termination of some EGS projects.

Through collaboration with researchers in Japan, we combine advanced laboratory experiments with cutting-edge numerical simulations to optimize fluid injection techniques, maximizing energy extraction while minimizing environmental risks such as induced seismicity. The findings could lead to safer and more efficient geothermal energy production and improved underground storage solutions for clean energy, contributing to global efforts to combat climate change and transition to renewable energy sources.

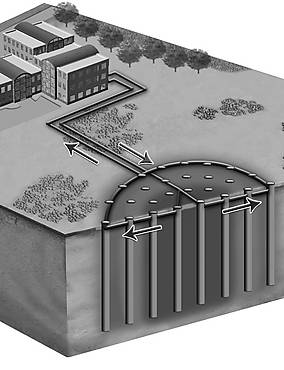

Feasibility Analysis of Deep ATES

In collaboration with EVN Waerme GmbH, the Chair of Geoenergy Production Engineering is undertaking a project to develop a screening tool for modeling, analyzing, and optimizing Aquifer Thermal Energy Storage (ATES) systems.

In the rapidly evolving energy transition sector, there is an urgent critical need for tools that can significantly reduce the running time and expenses of optimization processes. This project addresses that need by integrating the design of experiments (DoE), statistical analysis, and numerical simulation using the OpenGeoSys (OGS) into an open-source, Python-based screening tool specifically designed for efficient ATES analysis.

The tool will feature a response surface model (RSM) capable of approximating ATES system outputs in mere seconds. With this capability, the tool will streamline the optimization of ATES systems, making it an invaluable resource for enhancing energy efficiency and sustainability.

SimulAtion of CRAck propagation (SACRA)

Crack propagation driven by fluid pressure is known to take complex paths from both experiments and field observation under the presence of natural fractures, faults or bedding planes. Given the overwhelming laboratory and field observations, it is of most fundamental requirement for operators and regulators to have access to a robust and reliable predictive tool capable of tracking complex crack propagation and micro-seismicity induced, thereof to design operations and assess the associated risks.

For this purpose, we apply a variational phase-field model for complex crack development. One of the strengths of this approach is to account for arbitrary numbers of pre-existing or propagating cracks in terms of energy minimization without any a priori assumption on their geometry or restriction on the growth to specific grid directions.

This collaborative research mainly focusses on:

- shear slippage of existing surfaces (e.g. natural fracture),

- fracture dynamicity and acoustic wave propagation,

- coupled impacts with hydro-mechanics.

Finally, before upscaling the framework to a field scale, we plan to validate the outcomes against laboratory scale experiments and field tests.

Our publications:

- A phase-field fracture model in thermo-poro-elastic media with micromechanical strain energy degradation

- On poroelastic strain energy degradation in the variational phase-field models for hydraulic fracture

- Interactions of Hydraulic Fractures With Grain Boundary Discontinuities in the Near Wellbore Region

AI-Based Analysis of Water Temperature Predictions in Geothermal Systems

Univ.-Prof. Dipl.-Ing. Dr.mont.

Herbert

Univ.-Prof. Dipl.-Ing. Dr.mont.

HerbertHofstätter

Shallow Geothermal is an all-year available and clean renewable energy source, and groundwater temperature (GWT) is crucial in managing this resource for heating and cooling purposes. In urban areas, many human-made and natural factors affect the groundwater temperature.

Current groundwater temperature maps are derived directly from the interpolation of GWT measurements, indirectly from a combination of satellite data and building distribution, or based on numerical simulations.

However, these methodologies have to deal with insufficient real-time spatio-temporal data and the influence of local effects of anthropogenic heat sources on groundwater temperature. To solve these problems, integrating advanced artificial intelligence (AI) models with high predictive accuracy emerges as a viable solution.

This Project proposes an innovative approach to leveraging artificial intelligence (AI) to predict GWT considering real-time effective parameters. The aim is to strengthen groundwater temperature prediction in shallow geothermal energy applications.

A comprehensive dataset belonging to the Vienna city is used in this project to ensure accurate modeling, especially in an urban environment like Vienna. Therefore, a vast range of natural and artificial spatial and temporal data, including climate, geological, urban infrastructures, and hydrogeological data, is implemented to predict GWT and create accurate GWT maps.

Aquifer Thermal Energy Storage (ATES)

The objective of this project is to investigate the feasibility of High Temperature Aquifer Thermal Energy Storage (HT-ATES) in an industrial area in Austria. Leveraging the comprehensive understanding of the regional subsurface by OMV, the study employs a holistic approach involving various departments. The Petroleum Geology chair contributes to the development of the geological reservoir model, while Reservoir Engineering chair is responsible for conducting dynamic flow simulations. Additionally, Petroleum and Geothermal Energy Recovery chair conducts simulations related to wellbore flow and energy recovery. Lastly, the Energy Network Technology chair analyzes the regional heat demand and waste heat supply. By combining the expertise from these different fields, the project aims to thoroughly evaluate the potential of ATES.

Application of Alternative Material as Sucker Rod Strings

Dipl.-Ing.

Fatemeh

Dipl.-Ing.

FatemehFazeli Tehrani

Sucker Rod Pumps are the most common form of Artificial Lift Systems used in wellbores to improve the production rate. Within this system, the sucker rod string is the connection between the downhole pump and the surface drive unit. The aim of this project is to investigate the application of alternative materials and designs, as well as to analyze their practicality in comparison to the current conventional rod strings. Tests are planned to be conducted at the Pump Testing Facility at Montanuniversität Leoben, where a new test stand for this particular purpose is planned to be built. A successful replacement to conventional strings could lead to less structural loads, more efficient pumping, safer operations and an increase in the mean time between failures.

Application of Modern Mathematical Methods for Production Optimization

Application of Modern Mathematical Methods for Production Optimization

Dipl.-Ing.

Viorica

Dipl.-Ing.

VioricaSîrghii

Dipl.-Ing. Dr.mont.

Rudolf

Dipl.-Ing. Dr.mont.

RudolfFruhwirth

The field of applications for sophisticated mathematical analysis methods and self-learning software is infinite. New approaches are already widely applied in various areas such as in chemistry, medical diagnosis, image recognition and finance. Over the recent years, modern mathematical methods have been implemented more frequently to provide answers and/or to predict or resolve issues in the oil and gas production system.

In the past years, applications of data analysis in the oil and gas industry have become more common. This occurred particularly in areas such as reservoir production optimization, interpretation of well inflow performance and permanent downhole gauge data analysis. This project will demonstrate the potential of modern mathematical methods regarding decision making, efficiently leveraging the information in the collected data. Thus, increasing production rates and the mean time between failures, by reducing production impairments or improving production operations back-office processes.

ThermoDrill: A Novel System for Geothermal Projects

Dipl.-Ing. Dr.mont.

Patrick

Dipl.-Ing. Dr.mont.

PatrickEisner

MBA

Sepp

MBA

SeppSteinlechner

Costs of erecting wells for Deep Geothermal Applications represent a major part of the overall investment. Particularly when facing hard, crystalline rocks, the ROP becomes very low. To allow for better performance and such for easier risk assessment, an innovative technology is developed to provide much higher ROPs.

A combination of the rotary drilling technology with jetting technologies offers great opportunities for improving the drilling performance and reducing the need for fracturing.

SCALING: Ways to Reduce Production Limitations

Univ.-Prof. Dipl.-Ing. Dr.mont.

Herbert

Univ.-Prof. Dipl.-Ing. Dr.mont.

HerbertHofstätter

Dipl.-Ing.

Mohsen

Dipl.-Ing.

MohsenFakhari

Dipl.-Ing.

Yiwen

Dipl.-Ing.

YiwenXu

Scaling is one of the most problematic issues with energy production from reservoirs. Originating from hydrocarbons, formation waters, or from combinations of fluids, salts, and bacteria form barriers which reduce or stop the energy flow to the surface. Not only subsurface installations are affected, but surface installations as well.

The researchers of the Chair focus on applying physics rather than chemistry with significant success. This is not only positively influencing the production performance, it is also contributing to increased environmental care and reduced CO2 footprints.

BEER: Bio Enhanced Energy Recovery

Univ.-Prof. Dipl.-Ing. Dr.mont.

Herbert

Univ.-Prof. Dipl.-Ing. Dr.mont.

HerbertHofstätter

Bio Enhanced Energy Recovery is a system developed by the Chair in cooperation with leading industry partners in Austria and Germany. BEER represents the solution on the imminent needs for environmentally conscious energy recovery methods in geothermal reservoirs. All applied components are non-hazardous and most are even used within farming and food industries.

BEER is currently undergoing the first field tests and results will become available soon. The BEER technology is based on numerous pending patents.

Artificial Lift System Performance Optimization & Cost Reduction

The main targets of this project are to increase of the meantime between failures of the sucker rod pumping system as well as the stress reduction of system components. Other targets include the reduction of electricity consumption and the implementation of a monitoring real time diagnosis system, to further establish a predictive maintenance/failure prediction system.

Due to successful projects in the past, Sucker Rod Anti-Buckling System (SRABS) and Energy Efficiency (EnEff), research in the optimization of sucker rod pumps is ongoing. SRABS investigated the behavior of the subsurface components of sucker rod pumping systems with a strong emphasis on buckling. Whilst EnEff investigated the behavior of surface equipment of a sucker rod pumping system. Efficiencies and mechanical loadings can be evaluated through the measurements of current and voltage at the electricity supply grid. Other contributing aspects include the position of gear reducer shaft and walking beam, as well as the load at the polished rod and fluid pressures of a variable speed drive (VSD) driven system.

Project objectives

- A high optimization potential for sucker rod pumping installation has been shown in tests at the Pump Testing Facility, the recent field test and previous projects (SRABS and EnEff). Improvements and optimizations will increase the meantime between failures (MTBF). Additionally, the effective usage of electrical energy and reduction of installed converter hardware will contribute to a more positive environmental footprint along with a cost reduction.

- The goal of the project is to establish an efficiency monitoring system to detect, identify and understand undesirable situations, as well as conditions within the sucker rod pumping system.

- The monitoring system incorporates an upfront system optimization and continuous improvement during operation. Predictive maintenance is employed to analyze and evaluate the data gained by the monitoring system, as well as to increase the meantime between failures and useful life of system components. To do so predictive modelling is based on highly sophisticated mathematical models like neural networks.

Chemo Mechanical AGIng of Cementitious materials (MAGIC)

Aging of cement is essential in the context of radioactive waste disposal. Its consequences on mechanical characteristics and hydraulic properties are fundamental for the performance and safety assessment.

This project is to fill a gap in understanding the long-term physical integrity of underground cement constructions (rather than the chemical evolution alone). Using an open-source finite element platform (OpenGeoSys), we develop a micro-scale Hydro-Mechanical-Chemo (HMC) coupled model that can handle the interaction of chemical reactions and the subsequent mechanical damage development. Using a multiscale modeling framework, the micro-scale model is then upscaled to a field-scale model.

Downhole Dynamometer Sensors (DDS)

The continuing trend towards digitalization in the oil and gas industry is the field operators’ reaction to the market’s demand of reducing operating costs and increasing the lifetime of equipment. Advanced technology and procedures are essential to reach these goals. Sucker rod pumps (SRP) are a standard Artificial Lift System for liquids in mature fields and for the dewatering of gas wells. This type of lifting technology is well known and successfully used all over the world. However, previous developments during the last century were unable to prevent the system from failing under certain conditions. Several SRP failure analyses have shown that a significant fraction of system failures are the result of a broken rod string, caused by overloading or buckling. A major aspect that deters innovation is the lack of downhole data, which can be replaced using the DDS measurement system. This system consists of multiple DDS that are placed at specified positions along the sucker rod string. Each DDS records a three-dimensional stress field and motion profile of the sucker rod string, as well as the temperature of the produced liquid.

The data recorded allows for an extensive evaluation of rod string behavior. Aspects such as: rod string movement and loading, friction forces between rod guides and tubing, fluid pressure, rod torque, and volumetric parameters can be processed. The recording of several sensors is linked together to provide a comprehensive picture of the sucker rod string’s condition. The complementation of the value chain is achieved by using the recorded information to update rod string simulations. Nowadays, models for predicting the dynamic motion of the sucker rod string in the tubing string are available. Nevertheless, their accuracy depends on a variety of parameters, like friction and damping coefficients that are associated with the individual installation. To achieve a more stable design, data measured from the well to be optimized must be obtained. The meantime between failure (MTBF) can be increased significantly particularly in problem wells suffering from issues such as under paraffin precipitation or high complex geometry. Since the chair began developing the DDS in 2012, several field applications have been accomplished. Currently, the upgrading and implementation of additional features for the sensors is taking place.

Hydraulic Pump Development

Conventional Artificial Lift Systems are limited by their application with regard to depth, borehole trajectory, and chemistry of the produced media. The new hydraulic pumping system overcomes these limitations and assures a cost-effective production in harsh environments as well as low gravity oil reservoirs. The pumping system consists of a specially designed pump and piston combination, which is driven by a hydraulic pressure unit from the surface, without any mechanical connection. This new pump type has been designed, manufactured, and tested at Montanuniversität Leoben, Austria. To speed up the design process, the pumping concept of the hydraulic subsurface pump is validated using the open-source software toolbox.

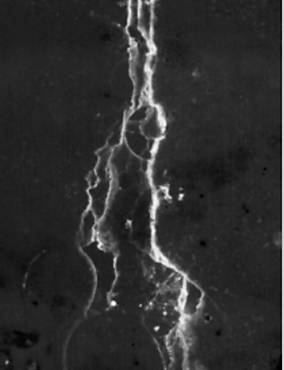

Numerical Modeling of Wormhole

Acidic fluid flow in geologic formations leads to mineral dissolution and, under certain circumstances, to localized dissolution forming a dendritic pattern known as wormhole. Such patterns of conduits and caves are often observed in the karstic aquifer and deliberately engineered in carbonate reservoir stimulation with acid injection. Two different kinds of instability are thought to cause wormholes. One is a heterogeneous property in rocks. The other is a process itself, such as reaction infiltration or viscous fingering. To assess each one properly, we need to separate one from the other. While most numerical studies rely on randomly seeded material heterogeneities to induce wormholes, Daccord and Lenormand (1987a) demonstrated that even water injection into a homogeneous plaster can form wormholes.

This project focuses on the process instability driven by reaction infiltration in homogeneous materials. We apply a phase-field approach, which diffuses a sharp interface continuously and shows that it can simulate wormhole without random seeds by accounting for the energy expenditure in the dissolution topology.

Daccord, G. and Lenormand, R., 1987. Fractal patterns from chemical dissolution. Nature, 325(6099), pp.41-43.

Our publications:

- A phase-field modeling study for reaction instability and localized fluid flow in carbonate rocks

- Phase-field modeling of wormhole formation and growth in carbonate matrix acidizing

Pump Testing Facility

Low oil prices push the demand for efficient production, especially in mature fields. Reducing the costs of artificial lifting by increasing efficiency is mandatory for extending meantime between failure, economic limit and increasing recovery factor.

For achieving these goals the Pump Testing Facility was established, to allow low risk, low cost, and high performance testing of new technologies, including various artificial lift systems. Montanuniversität Leoben constructed this facility to overcome the enormous field testing costs and to speed up innovation. The testing facility is able to test oil field equipment under conditions occurring in depths up to 500m.

As an integral part of the chair’s research programs, new technologies, self-developments and patents will be tested before being applied in fields. The pump testing facility is used to provide services to the industry and to test according to industry needs. In close cooperation with the industry, this pump testing facility will be expanded to cover more special operational modes and events that may occur in the field.

Sucker Rod Anti-Buckling System

During times of low oil prices, cost optimization is vital. Especially in mature oil fields, the reduction of lifting costs by increasing the mean time between failure and the overall efficiency helps stay economical and increases the final recovery factor. Today a significant portion of artificially lifted wells use sucker rod pumping systems. Although its efficiency is in the upper range, compared to other Artificial Lift Systems, there is room for improvement and system optimization. The Sucker Rod Anti-Buckling System (SRABS) keeps the entire rod string under tension using technology based on a redesign of the standing valve and the advantageous use of the dynamic liquid level. This results in complete buckling prevention and a reduction in the overall stress in the sucker rod string. The pump is already field tested and previous experience is being implemented into the design of the new pump type.

Sucker Rod Pump Valve Movement Analysis

Investigations have shown that ball valves of sucker rod pumping systems open and close not only at the lower and upper dead center, but also in between, depending on the stroke characteristics. This fact can influence the volumetric efficiency and wear of the ball and seat significantly. To find a solution to this problem, two major points need to be solved – understanding the movement of the ball valves and the exact motion of the downhole plunger.

In the past, extensive simulation efforts were spent to describe the motion of the standing and traveling valves of the sucker rod pump. The simulation performed by AC2T has shown very promising results. Unfortunately, the model needs to be verified in order to continue. This project enables the verification of the existing CFD model.

Virtual Flow Meter Project

Dipl.-Ing. Dr.mont.

Patrick

Dipl.-Ing. Dr.mont.

PatrickEisner

Nowadays, digital transformation is no longer an option that only few global players choose to pursue – it is becoming an integral part of almost every company’s portfolio. Together with various industry partners, the Chair of Petroleum and Geothermal Energy Recovery has joined the journey towards digital transformation. In a current project, a virtual flow meter is being developed to greatly aid in obtaining a deeper understanding of hydrocarbon flows. By applying concepts of machine learning, this virtual measurement device will be able to adapt to changing boundary conditions in the field, whilst simultaneously maintaining its accuracy and flexibility. To simulate various field conditions for the tool’s learning capabilities, three-phase experiments at ideal conditions are being conducted at the chair’s unique pump testing facility. The virtual flow meter will not only lower the operational cost, but also improve the decision-making process based on artificial intelligence applied in the field.

From Digital Rock Physics to Stochastic Reservoir Modeling

Data from the Digital Rock Physics and Special Core Analysis will be used to understand the influence of uncertainties of multiphase-flow parameters on predictions from reservoir modeling. By integrating the results with petrophysical records, the project strives for a proper stochastic reservoir modeling workflow. Possible applications include water flooding, enhanced oil recovery, geological CO2 sequestration, geothermal reservoirs, and many more.

Hydrogen Storage and Methanation on Field Relevant Scales

The project investigates geological hydrogen storage and hydrogen conversion for large-scale energy storage on field relevant scales. In this combined experimental and numerical study, the focus is set on finding the limiting factors for gas conversion rates, storage, and flow capacities. It is planned to carry out meter-scale core-flooding experiments supported by computer-tomography imaging and in-line gas analysis to monitor microbial activities and the associated flow performance. To understand and scale the underlying complex reactive transport process, the experiments are interpreted through numerical simulations. The results will be transferred to the field scale and the experimental and numerical methods used will be further developed.

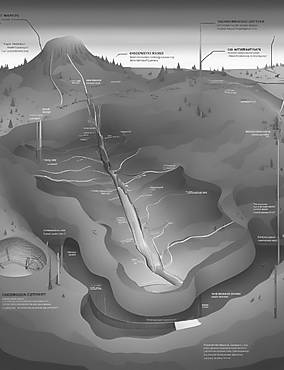

Subsurface Processes and Risks During Carbon Storage

CO2 can be injected in various ways – e.g., as supercritical fluid, in form of carbonated water, or as CO2 foam. For the different operational modes, CO2 is stored in different phases influencing storage capacity and storage security. This combined experimental/numerical study investigates how efficiently the pore space is used in different injection schemes, addressing the respective storage capacity, and CO2 mobile referring to storage security.

Furthermore the project studies the extent to which the injectivity is impaired by salt precipitation due to supercritical CO2 injection. This is essentially a question of dry-out kinetics and the resulting capillary transport of minerals dissolved in the formation water, which is still poorly understood. The project combines meter-scale CT-based core flood experiments with experimental-scale and field-scale modelling of the underlying reactive transport processes.

Cover image credit: Shepherd, L.-A., 2005. Options for storing CO2 in deep underground geological formations (after Cook, 1999). Cambridge: Cambridge University Press.

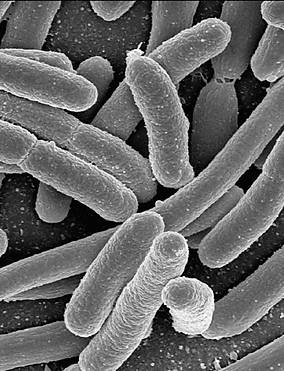

Biopore

In this project, the influence of microbial growth in the subsurface on hydraulic rock properties in single and two-phase flow is being investigated. The engineering applications are manyfold, but the project is specifically aimed at the underground methanation of hydrogen from renewable energy sources and carbon dioxide.

Through the combination of microfluidic experiments and numerical flow simulation, detailed insight on the biomass growth and the change in the hydraulic properties of the porous medium and the biomass within are obtained. These changes determine not only the storage and flow capacity of reservoirs, but also the nutrient-conversion rates, respectively the methanation rate in the present case. The project focuses on the following research questions: (a) To what extent does the permeability of porous media change with increasing biomass with regard to changing porosity? Can it be quantified by a porosity/permeability relationship? (b) What is the exact distribution of the biomass in the pore space? If the biomass distribution limits the substrate (nutrient) supply to the microorganisms, the in-situ gas conversion rate would likely not be economic.

Reservoir Characterization: The Effect of Natural Fractures on Production Data

The first phase of this project is related to stress modeling and studying the relationship between fractures and production data of a super-giant carbonate reservoir. Image logs such as FMI log data are used for stress regime analysis and a fracture study of a giant fractured carbonate reservoir with more than 80 years of production. Through the interpretation and analysis of image logs, the direction and magnitude of the stresses and their associated fractures are obtained. By reviewing field and well production data, their correlation with already mapped fracture data is studied. Thus, the relation between fracture intensity and presence of open fractures is compared with the field production data. Upon construction of the Descriptive Fracture Network (DNF) model of the prototype area, fracture porosity, fracture permeability, sigma parameter, and block size are calculated. Accordingly, an estimation of the block size for each block in the dynamic simulation model can be obtained. With this project, we aim to provide an understanding of production challenges of the super-giant carbonate reservoir and more successful planning of conceptual and basic EOR experiments for the field.

Digital Rock Physics

A Digital Rock Physics workflow is being developed and introduced into OMV, with the focus on multi-phase flow parameters. The project aims to reduce costs and decision-making time in comparison to conventional workflows, such as SCAL. At the same time, the project aims to realistically map the petrophysical uncertainties as input for stochastic reservoir modelling. To be computationally effective, the project uses a morphological approach that is being developed in cooperation with Math2Market. The project is approached by benchmarking the simulated and experimentally determined pore-scale fluid distributions, and by comparing the simulation results to classical SCAL experiments.

Further areas of investigation are the incorporation of unresolved pore space by means of effective porous-media properties and the simulation of two-phase flow properties from unconsolidated rock based on grainsize distributions and other basic petrophysical data.

EmulPore

Dipl.-Ing.

Ahmad

Dipl.-Ing.

AhmadKharrat

The EmulPore project investigates emulsion formation during water-oil displacements under various flow conditions. It is based on a Lab-on-a-Chip approach using microfluidics. The microfluidic structures represent decomposed petrophysical properties of reservoir rocks (from the Vienna basin), and generic microfluidic structures are used. The fluids being tested are crude and refined oils as well as alkali and surfactant solutions. Emulsification under flow conditions is being systematically investigated and compared to classical phase behavior experiments. Furthermore, the results will be compared to the phase behavior and properties observed in droplet experiments (spinning and pendant drops).

In the frame of the project, microfluidics will be combined with dynamic light scattering in order to characterize tight emulsions. Moreover, small angle x-ray scattering will be performed to characterize droplet sizes in classical phase-behavior experiments. An implementation of the methodology into the OMV EOR workflow is foreseen.

Reflecting Oil: Arts-Based Research on Oil Transitionings

The project "Reflecting Oil" offers an innovative and multi-perspective reflection on oil, one of the most important fossil resources of modern life. This ubiquitous but elusive substance is being reflected in to four of its elements. Its material element as a chemical mixture, in its global element as a geopolitical cause of conflict and environmental pollution, and in its symbolic element as a worldwide object of desire. Through the application of art-based research methods, the raw material is being illuminated in a new way, subsequently providing information about sustainable energy.

Throughout the course of the project, the crude oil is being artistically examined through a variety of experiments. These experiments are carried out in the laboratories of the Department of Petroleum Engineering, Montanuniversität Leoben. The research is supported by scientists and an interdisciplinary team of experts from the University of Applied Arts Vienna, the University of Alberta and Waterloo (Canada) and other academic institutions. The implementation of “Petrocultures” in the Leoben and Vienna teaching programs is forseen.

Cover image credit: "Crude Oil Experiment - Hele Shaw", Ernst Logar, Bildrecht 2020

Technology Development Roadmap for Carbonate Reservoir Exploration and Production

The objective of the first phase of the carbonate reservoir exploration technology project is to provide a road map to the challenges of the exploration of carbonated fractured reservoirs. Namely, reservoir rock heterogeneity (rock characterization), reservoir fluid heterogeneity (fluid characterization), qualitative and quantitative of fractures (fracture characterization), well testing & fluid modeling, and formation evaluation technology development.

Chemical Interaction of Xanthan Polymers in Porous Media by Micromodel and Coreflooding

Chemical Interaction of Xanthan Polymers in Porous Media by Micromodel and Coreflooding

Karsh.A

Ali

Karsh.A

AliMirzaalian Dastjerdi

The prospect of using polymer for the EOR method has been recognized for several decades and has been successfully implemented in a wide range of fields worldwide. However, its application has been hindered due to economic and mainly technical conditions (salinity, temperature, adsorption, etc.). Cost-effective polymers which can tolerate the harsh reservoir conditions are desirable.

This project focuses on the feasibility of using a new Xanthan polymer for EOR. The first phase of the project aimed to investigate the new polymer's mechanical and chemical interaction in porous media by microfluidics. Based on the rheological and microfluidic results, the polymer was better resistant to temperature and salinity than the polyacrimilde. The second phase of the project focuses on other essential polymer characteristics, such as adsorption, critical micelle concentration, and finally, the oil recovery improvement compared to other polymers in the field.

Lab on a Chip for Optimizing EOR Fluids

The project focuses on the investigation and optimization of displacement efficiency of alkaline flooding with a focus on the Vienna basin. Different chemical injection-water compositions and different crude oils form the Vienna Basin are tested with a Lab-on-a-Chip approach; we use microfluidics with high-end optical and fluorescence microscopy as a base experimental technique. The data is being analyzed based on fluid-phase topology and statistical methods to increase the sensitivity of chemical screening. The experiments are being supported by classical phase-behavior experiments, IFT measurements and contact angle experiments.

In the frame of the project, experimental results should be reproduced in 3D through mCT (micro computed tomography) imaging-based micro core-flood experiments using porous glass, a material that is directly comparable to the microfluidic devices.

Explicit Continuum-Scale Modeling for Low Salinity Water Flooding

Dipl.-Ing.

Kata

Dipl.-Ing.

KataKurgyis

Karsh.A

Ali

Karsh.A

AliMirzaalian Dastjerdi

This project aims to setup a world-class long-core CT-based core flood experiment with an explicit numerical interpretation tool for experimental design, history matching experimental results and upscaling. The setup is meant to conclusively investigate and develop complex displacement processes. Currently, the project is focused on aqueous EOR processes, but aiming towards CO2 injection for sequestration and hydrogen storage/conversion for energy storage in the future. On the hardware side, we foresee rock-samples with the dimensions of 3-inch diameter and 1m length. The length scale is already “field relevant” and allows a conclusive evaluation of displacement efficiency. The hardware is currently under construction and is expected to be operational by the end of 2020.

For the explicit description of the displacements and respective chemical interactions, an open-source simulator (DuMuX) is being used. So far, different physiochemical processes related to the low-salinity water flooding have been implemented (collaboration with Stuttgart University, Stuttgart, Germany). This simulation tool allows for an explicit implementation or rock-fluid interactions, which is advantageous for understanding and quantifying reactive-transport processes.

Underground Sun Storage

“Underground Sun Storage” is a holistic and multidisciplinary project on the storage of renewable energy as hydrogen/methane mixtures in depleted gas fields. It was the first project of its kind, combining experimental and numerical research with a pilot field test in the Lehen field in Upper Austria.

The work package of the Chair was related to transport modelling, focusing on estimating hydrogen losses due to fluid transport mechanisms in the reservoir and in the cap rock. In a second work package, chemical interactions between the injected fluid and the rock formation were studied. For this, geochemical reactions were modelled with different degrees of complexity to estimate hydrogen loss by reactions on the time scale of storage cycles.