Research Infrastructure

Excellent hardware and software is the base for leading-edge research, service and lecturing

Montanuniversität’s ongoing investments in new infrastructure are the result of a long history of outstanding achievements. The DGE building inaugurated in July 2016 and the DGE laboratory building next to it, are the most recent proof of the importance of DGE.

DGE Building

Three chairs, one department, one building: Drilling, Production and Reservoir Engineering

High-tech, multimedia-equipped lecture and seminar rooms

Meeting areas for agile and open project discussions

DGE Laboratory Building

Leading-edge laboratory equipment and software for research, training and lecturing

Highest HSE standards of laboratory facilities, procedures and processes

The research facilities of the three chairs concentrated in one building

Flooding & Imaging Laboratory

Imaging of fluid flow in porous media for investigating fluid displacement mechanisms

Leading-edge experimental capability: microfluidics, medical computed tomography CT (medical computed tomography) based long-core flooding unit, micro-CT-based core flooding unit, interfacial properties by pendant and spinning drop, image processing and analysis (digital rock physics)

Currently applied to Enhanced Oil Recovery, geological hydrogen storage and carbon sequestration

Reservoir Simulation Laboratory

Pore-scale flow modeling (GeoDict, digital rock physics)

Continuum-scale modeling in DuMuX in collaboration with University of Stuttgart, Enhanced Oil Recovery

Tough2 and ToughReact modeling for geothermal engineering and CO2 sequestration

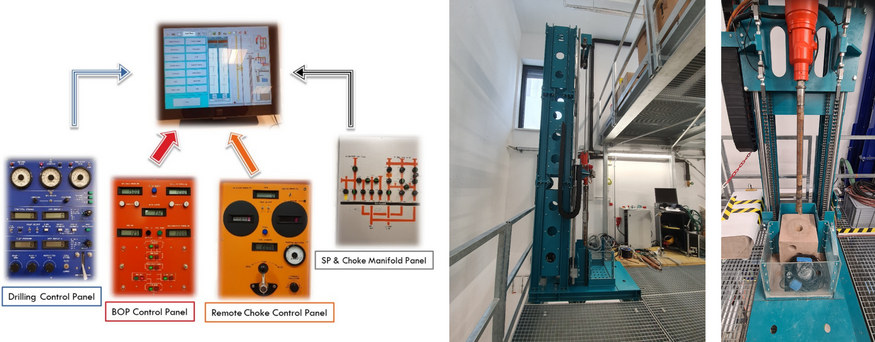

CDC Drilling Digitalization Laboratory

CDC Mini-Rig for experimental, hands-on, research-based learning

High end, mobile well control simulator for teaching and training

Real-Time Operating Center (RTOC) replicates industry conditions for monitoring well performance, and analysis

CDC Digital Flow Laboratory (DFL)

Innovative non-invasive and invasive sensors development and testing for improved measurement accuracy and safety in operations

AI-driven automation models to enhance decision-making and increase operational efficiency

Development of physics informed models (PIMs) for accurate simulations and in-line analysis for various application

CDC Energy Storage and CCS Laboratory

Using high-end technologies to reduce uncertainty in H2, CH4 and CO2 Storage

Using digital solutions to improving the chance of success for CCS, Geothermal Exploration and making faster decisions

Analyzing the near-wellbore zone as a whole rather than separate components

CDC Well Integrity and Cementing Laboratory

Evaluates wellbore material performance throughout the well's life cycle

Assess cement aging and bonding under varying operational conditions

Performing required API tests for subsurface well cementing operations

Pump Testing Facility

Sucker rod pump including the anti-buckling system

Artificial lift systems such as electrical submersible, progressive cavity and hydraulic pump

Leading edge control unit for various performance test scenarios

Simulation Laboratory

Oil & Gas Production Optimization

Optimization of Geothermal Energy Recovery

Sustainable Remodeling of Uneconomic Wells

DGE

Department

Chairs

University

Partners

Apply

Enrollment Process

Future Students

Offers for Students

Student Exchange

Jobs at DGE

Academics

BSc Geoenergy Engineering

MSc Geoenergy Engineering

MSc Petroleum Engineering

MSc Double Degree Petroleum Engineering

MSc Industrial Management and Business Administration

PhD Petroleum or Geoenergy Engineering

Research

Research

About

News

News

Events

Alumni